Our vision is to cost-effectively reduce the worldwide hydrocarbon influence through combustion nanotechnology. We strive to provide world class adaptation logistics, avant product support, industry leadership, and superior research to hydrocarbon dependent organizations.

About Bair Research

Bair Research assists fossil fuel | hydrocarbon dependent businesses by applying a proven unique (CO2) / (GHG) greenhouse gas solution globally that chemically reduces all hydrocarbon consumption through nanotechnology. We have over 40 years in mechanical systems analysis, failure analysis, systems repair, and re-engineering. We specialize in electromechanical systems, computer interface diagnosis, repair, tool design and fabrication.

Bair Research streamlines fuel efficiency through simply installed nanotechnology that chemically enhances hydrocarbon combustion. Our solution employs simple delivery of complex hydrocarbon combustion chemistry that provides substantial fuel savings, a cleaner environment and reduced (GHG) greenhouse gas emissions. We improve air quality. Our current technology is ready, scalable and available right now. Given US powerplant buy-in Kyoto and Paris can be met within years, we are confident of a gigaton (CO2) / megaton (GHG) greenhouse gas reduction by 2028 can be achieved with a fraction of global power plant participation.

With over 25 years nanotechnology catalyst combustion systems application, 15 years exhaust emissions regulations research and 18 years nanotechnology hardware design and manufacturing logistics, From our many years of experience we have created solutions that offer tremendous ROI for our clients through fuel savings, downtime, emissions credits and cycle/turnaround time performance. Our nanocatalysts cannot fail if properly delivered, maintained and administered as instructed by our consulting experts.

Bair Research’s vision is for global implementation of our current solutions and use worldwide in all hydrocarbon energy sectors regardless of organization. Our ongoing research into new effective chemistry shows promise for the mitigation of mercury and sulfur emissions species. Preliminary results indicate improved effectiveness and versatility of the technology’s phenomenal performance. Bair Research will always continue to improve its solutions performance, adaptability and modularity for all hydrocarbon consumers although our focus initially will be large consumers like commercial maritime ships, cruise lines, over the road semi trucks and power plants. IP protection for investors; trade secrets, current patent-pending, and new patents potential.

We are confident in our solutions which offer value, predictable return, are simple to apply, and get outstanding results.

Nanocatalyst Case Study

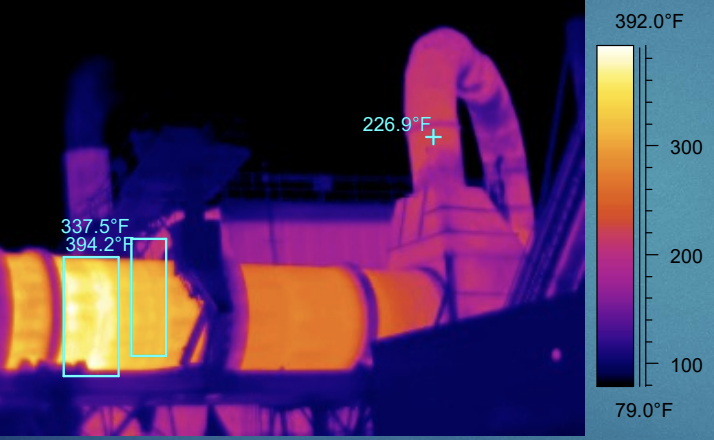

Infrared Thermography Axial Flow

Asphalt Plant

A nanocatalyst demonstrates dramatically improved thermal efficiency. Increased firebox

and lower exhaust temperatures. Plant is now capable of higher output and fuel

savings. Higher output increased tons per hour and potential delivery radius.

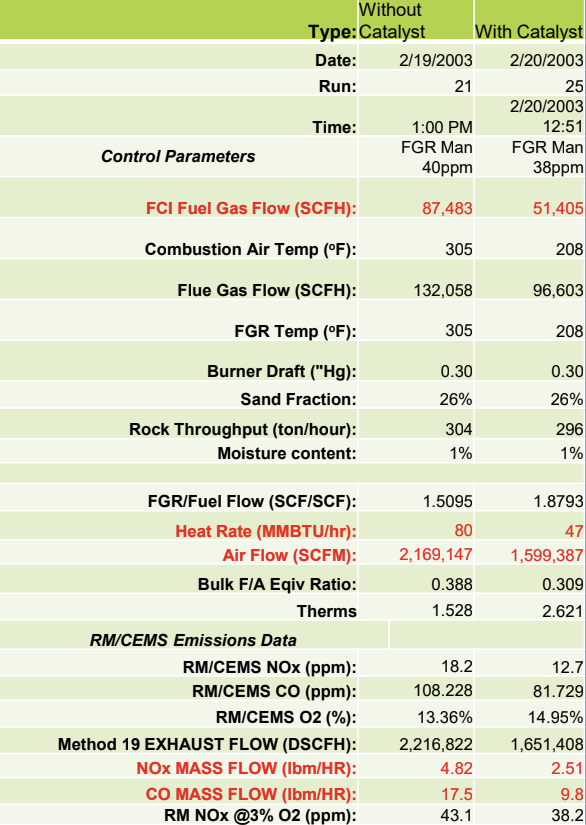

Southern California Counter Flow Asphalt

Plant Annual Compliance

Test

Impressive Results

• 26% less air

• 41% less fuel

• 47% NOx corrected (mass flow

lbm/HR)

• 44% reduced CO (mass flow

lbm/HR)

• All reductions accomplished while

maintaining production levels

• In accordance with US and

California EPA (CARB) compliance analysis rules and varying fuels. Heat Rate

here is BTU / Caloric value and is not a calculation of efficiency.

(Case conducted by Geoff Ashton – California Industrial Emissions Technician)

Learn More

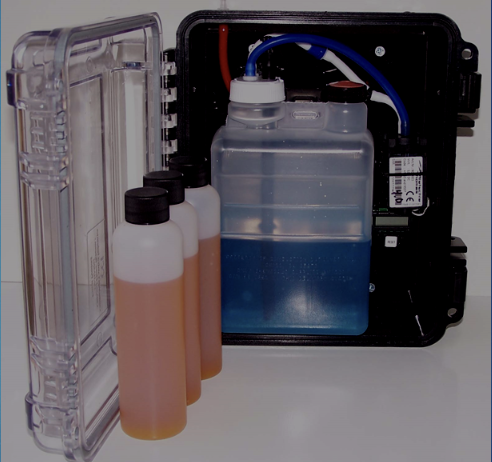

Nanocatalyst Injection System

Small-Intermediate Scale

Delivery System Technology

- Patent Pending

- Catalyst recharge set to maintenance interval 4,5,600 hour (3) 400 Hr. applications shown

- NCIS 20 GPH/2.4 MMBtu Hr.

- NCIS delivers catalysts at a ratio of parts perbillion (ppb) to the weight or heat value of the fuel

- Applications larger than 240 gph or equivalent will require consumption specific dispensers

- 20, 40, 60, 80 GPH modular systems available

- Intermediate consumers may require multiple

- NCIS – Nanocatalyst Injection System – Dispensers

- Large-scale may require Direct Injection (DI) with multiple redundancy

NCIS is not an additive. Though a consumable, our simple system is cost-effective combustion catalysis providing substantial ROI. Uniquely introduced into the intake/combustion air and serviced at oil change intervals or in the case of power plants automatically replenished.

Predictable Returns

Outstanding Results

What People Say About Bair Research’s Technology

A Unique, Proven, Effective, Scalable Environmental Solution that Delivers Predicable Returns and Outstanding Results.

Unique | Proven | Effective | Scalable

For a viability study it was great data. The real fun will be the fine tuning and long term benefit in fuel savings. Without the catalyst we go off the CO analyzer scale at 1000ppm. With the cat we hold a solid 50ppm. At the burner front, the flame is noticeably smoother.

Geoff Ashton

California Industrial Emissions TechnicianI just cant put the excitement I felt that night while running a Cat 3408 on a dyno at Holt Caterpillar. 15% decrease in the amount of fuel it took to make 10% more horsepower and witnessed opacity go down from 57 % to 9% with a triple snap test. Most remarkable product.

David Marchiori

Former Maintenance Manager – S&P 200The injection of nanocatalysts in a Deutz MWM 916-6 diesel engine substantially reduces the amounts of CO and NO, in the diesel exhaust stream. Nanocatalysts are a practical means of reducing operating costs to pennies on the dollar per gallon of diesel fuel.

Dr. Elliott P. Doane

Former Senior Chemist – Kerr-McGeeContact Us Now! Begin Creating Profitable Solutions.

We’re taking on new clients, investors and projects. Join us in creating environmental change.

Office

Bair Research & Development LLC

545 3rd Street #2118

Monument, CO 80132

Hours

Mon-Fri: 8am – 5pm

Sat: 8am – 9pm

Contact Bair Research Now!

Bair Research provides exceptional consulting for hydrocarbon dependent organizations

A Unique, Proven, Effective, Scalable Environmental Solution that Delivers Predicable Returns and Outstanding Results.

Unique | Proven | Effective | Scalable